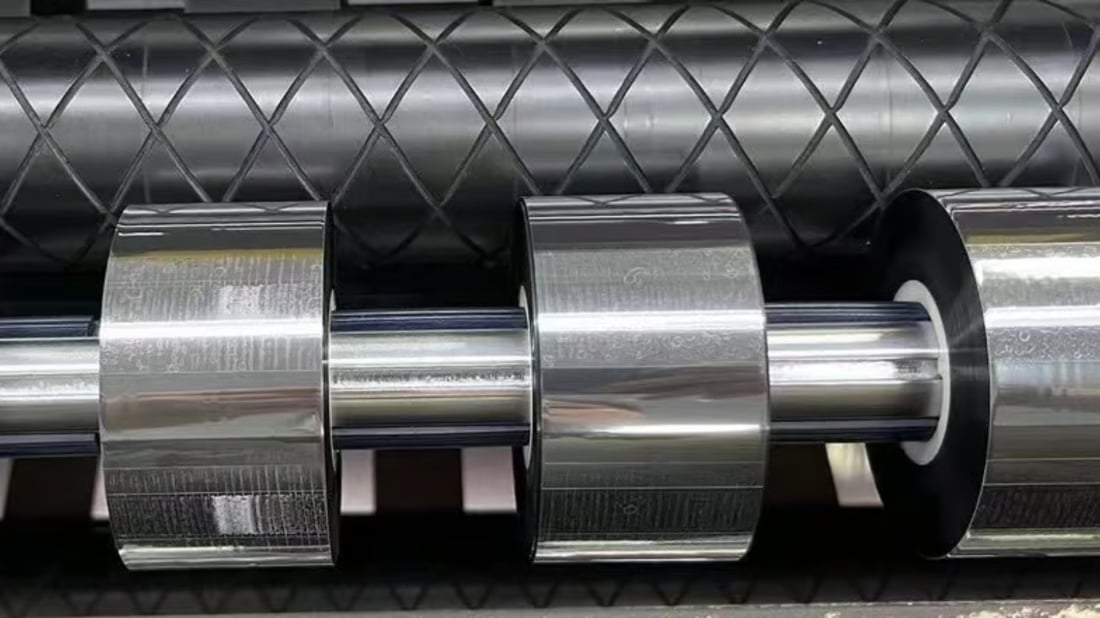

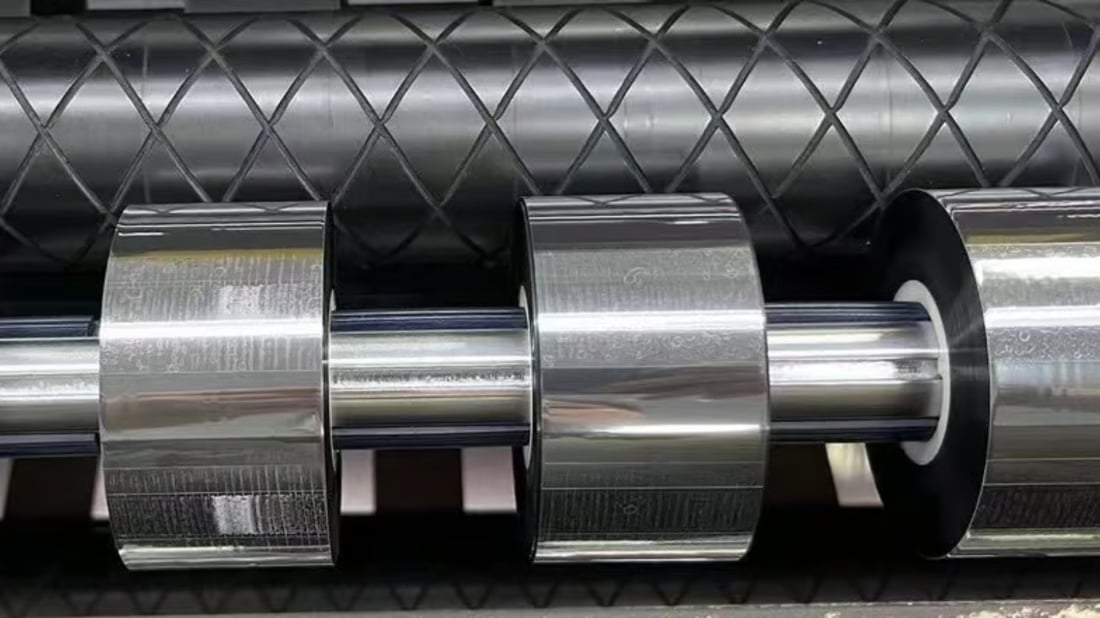

Thermal transfer ribbon is a printing ribbon technology used for creating high-quality labels and barcodes. The ribbon is made of a thin polyester film that is coated with a heat-activated adhesive, and a layer of ink on top of it. The ribbon is fed through a thermal transfer printer, which applies heat to the ink layer, and transfers it onto the label or tag material.

Types of Thermal Transfer Ribbon

There are different types of thermal transfer ribbon, such as wax, wax-resin, and resin ribbons. Wax ribbons are the most common and cost-effective option for printing standard labels. Wax-resin ribbons are more durable and resistant to smudging and scratching, making them suitable for printing product packaging or inventory tags. Resin ribbons are the most durable and expensive option, with excellent resistance to chemicals and extreme temperatures, suitable for printing labels used in harsh environments.

Factors to Consider When Choosing Thermal Transfer Ribbon

When choosing a thermal transfer ribbon, there are several factors to consider. The label material, printer resolution, type of printer, and intended use of the label are all important factors to consider. A low quality label material may cause the ink to smear or bleed, while a high-resolution printer requires a ribbon with a higher level of ink transfer. It is also important to choose a ribbon that matches the type of printer being used.

Advantages of Thermal Transfer Ribbon

Thermal transfer ribbon offers several advantages over other label printing technologies, such as high-quality print output, durability, and versatility. Thermal transfer labels can be printed with barcodes, text, and graphics that are clear and readable, even at small sizes. Thermal transfer labels are also resistant to fading, smudging, and scratching, making them suitable for long-term use in harsh environments.

Applications of Thermal Transfer Ribbon

Thermal transfer ribbon is widely used in various industries such as healthcare, logistics, manufacturing, and retail. It is used for printing product labels, asset tags, inventory tags, shipping labels, and other types of labels. Thermal transfer technology is also used for printing ID cards, wristbands, and security labels.

How to Store Thermal Transfer Ribbon

It is important to store thermal transfer ribbon properly to ensure it maintains the correct print quality. Thermal transfer ribbons should be stored in a cool, dry place, away from direct sunlight and high temperatures. It is also important to keep the ribbon in its original packaging to protect it from dust and dirt.

Common Problems with Thermal Transfer Ribbon

Common problems with thermal transfer ribbon include ribbon wrinkling, inconsistent print quality, and ribbon sliding. Ribbon wrinkling can occur if the ribbon tension is too high or the printer head pressure is too low. Inconsistent print quality can be caused by printer settings or a dirty printer head. Ribbon sliding can occur if the ribbon is not installed correctly in the printer.

Maintenance of Thermal Transfer Printer

Regular maintenance of the thermal transfer printer is important to ensure optimal performance and print quality. This includes cleaning the printer head and rollers, adjusting the printer settings, and replacing worn out parts. Proper and timely maintenance can significantly extend the lifespan of the printer and reduce repair costs.

Cost of Thermal Transfer Ribbon

The cost of thermal transfer ribbon varies depending on the type of ribbon, the length and width of the ribbon, and the manufacturer. While wax ribbons are cheaper than resin ribbons, a low-cost ribbon may not necessarily be the best option for long-term use. It is important to choose a ribbon that matches the label material and intended use of the label.

The Future of Thermal Transfer Ribbon

Thermal transfer ribbon technology has come a long way since its inception and continues to evolve. The demand for more efficient and cost-effective label printing solutions has led to the development of new thermal transfer ribbon formulations that offer higher print quality and durability while minimizing waste. The future of thermal transfer ribbon is undoubtedly bright, as it continues to find more uses in different industries.

Quote Inquiry

If you have any questions, please let us konw asap!