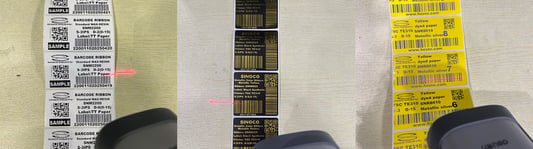

What is a thermal transfer printing machine?Thermal transfer printing machines are a type of printer that uses heat to transfer ink onto various materials. This process is commonly used in industries such as manufacturing, packaging, and labeling to create high-quality, durable prints.How Does a Thermal Transfer Printing Machine Work?These machines work by melting a wax or resin-based ribbon onto the material being printed. The heat generated by the printhead transfers the ink onto the material, resulting in a permanent and smudge-proof print.Benefits of Using a Thermal Transfer Printing MachineOne of the main advantages of using a thermal transfer printing machine is the high print quality it offers. These machines can create crisp, precise prints that are resistant to fading and smudging. Additionally, thermal transfer printing is suitable for a wide range of materials, including paper, plastic, and fabric.Applications of Thermal Transfer Printing MachinesThermal transfer printing machines are commonly used in industries such as food and beverage labeling, clothing tags, and product packaging. These machines are versatile and can be used to print barcodes, logos, and text on various materials.Types of Thermal Transfer Printing MachinesThere are two main types of thermal transfer printing machines: direct thermal and thermal transfer. Direct thermal printers use heat-sensitive paper that blackens when heat is applied, while thermal transfer printers use a heated ribbon to produce long-lasting prints.Choosing the Right Thermal Transfer Printing MachineWhen selecting a thermal transfer printing machine, consider factors such as print volume, desired print quality, and budget. It is essential to choose a machine that meets your specific printing needs and can handle the materials you will be printing on.Top Brands of Thermal Transfer Printing MachinesSome of the top brands of thermal transfer printing machines include Zebra, TSC, and Sato. These brands are known for their reliability, durability, and high-quality prints. Be sure to research different brands and models to find the best fit for your business.Maintenance and Care Tips for Thermal Transfer Printing MachinesTo ensure optimal performance and longevity of your thermal transfer printing machine, regularly clean the printhead and replace the ribbon and labels as needed. Proper maintenance will help prevent issues such as poor print quality and printhead damage.Cost of Thermal Transfer Printing MachinesThe cost of a thermal transfer printing machine can vary depending on factors such as brand, model, and features. Basic models suitable for small businesses can start at a few hundred dollars, while more advanced industrial-grade machines can cost several thousand dollars.ConclusionIn conclusion, thermal transfer printing machines are versatile and efficient tools for creating high-quality prints on various materials. Whether you are in the manufacturing, packaging, or labeling industry, investing in a thermal transfer printing machine can help streamline your printing process and ensure professional results.Quote Inquirycontact us